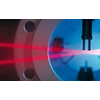

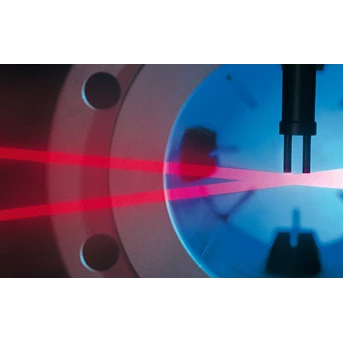

To achieve the desired accuracies using COMBIMASS® thermal gas flowmeter, a minimum inlet and outlet straight pipe runs must be considered when installing according to DIN ISO 5167-1 as a result of the actual piping, flow profile irregularities and the necessary calming distances.

If no sufficient calming distances are available, the desired measuring accuracy can possibly be achieved with a special calibration of the mass flowmeter by simulating the actual site conditions in our CAMASS® Calibration Lab with the same field operating process conditions under real load conditions and even the same piping layout.

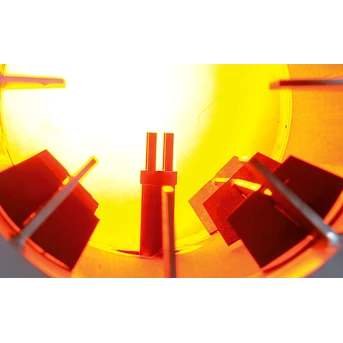

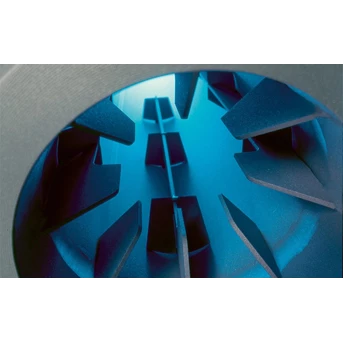

HIGHLIGHT

- makes a defined and reproducible flow profile

- improves accuracy of flow measurement significantly

- reduces required straight inlet and outlet pipe runs, thus reduces costs

- very low pressure drop

- rugged design, not sensitive to dust particles

- easy installation and maintenance

- dampens flow pulsations

- different types and materials available

- special types with integrated flowmeter can be supplied (total length only 3D)

Flow meter