- Designed to build up high-performance multipoint measuring systems easily

- May be combined with any flow transmitter of the COMBIMASS® series

- Highly precise flow rate measurement of gases even with short inlet and outlet pipe sections, large nominal diameters or rectangular ducts

- Redundant gas flow measurement for the purpose of safety precaution or economical control of critical processes

- Suitable for complex applications such as flow metering of mixed gases with variable composition

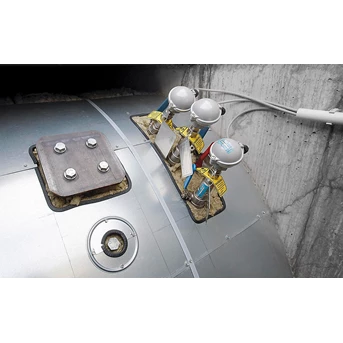

A COMBIMASS® multipoint system allows precise measurements of flow rate of pressurized air and technical gases even with short inlet and outlet pipe sections, nominal diameters larger than DN 500 or rectangular ducts. In such situations flow profile distortions may occur, which normally lead to errors in flow metering of gases. All flow meter of COMBIMASS® series (basic, eco, eco-bio+) can be used in combination with the COMBIMASS® multi electronics in a field housing. The flow meter are powered by the field housing. Analog output signals or current loop signals can be read into the electronics for further processing and signal compensation.

By installing multiple measuring points over the cross-section of the pipe or duct and averaging the flow signals, COMBIMASS® multi enables accurate and reproducible results even in such difficult applications. The COMBIMASS® multi was designed to build up a high performance multipoint system for thermal flow rate measurement of gases. There can be a number of flow transmitters connected to the PLC-based COMBIMASS® multi electronics.

For applications, which are critical from a safety point of view or in such cases where faulted re-sults may cause considerable costs due to uneconomical process control, COMBIMASS® multi enables redundant monitoring of gas flow rates. Permanent functionality checks of the connected sensors as well as continuous plausibility checking of the flow signals guarantee outstanding relia-bility of the system. In case of any inconsistency or if one of the connected sensors fails an alarm will be immediately released. In such case of malfunction, COMBIMASS® multi automatically con-siders only those signals of the working flow sensors for signal processing, thus largely avoiding erroneous measuring results.

For indication of the measured flow rates or selected compensation parameters as well as for programming of the multipoint system the PLC is placed in the field housing for indoor or outdoor installation, powered with 24 VDC or 230 VAC. The 4.3”-touch-TFT graphic display (7” size can be supplied as an option) can be placed on a holder inside the cabinet or in the door of the cabinet with a protection cover (if mounted outdoors). The field housing can be made from stainless steel or plastics, for wall mounting or mounted on a rack.

All kinds of data transmission are available: analog signals, Ethernet Modbus TCP, Modbus RTU, Profibus, Profinet or Ethernet IP. COMBIMASS® multi allows indication and checking of the actual reading of any of the connected flow transmitters in the field. For monitoring of flow rate or temperature limits up to three switch points can be field set using additional relay outputs. Via those relay outputs either an alarm may be released.

COMBIMASS® multi features processing of external control signals in order to run complex appli-cations. In order to enable monitoring of those external control signals an analog input as well as a relay input are available.

Flow control valve